Computed accuracy (fixed wing aircraft)

The computed accuracy is determined analytically from sensors manufacturer datasheets assuming that the wing area, the total wetted area, the flight weight, the wing aspect ratio and the Oswald efficiency factor are known.

| Accuracy | |

|---|---|

| Electrical efficiency | 1.80% |

| Propeller efficiency | 3.02% |

| Aerodynamic efficiency (Cfe) | 2.53% |

| Lift Coefficient (Cl) | 2.00% |

| Rate of climb | 0.25% |

| Accuracy | |

|---|---|

| Electrical efficiency | 1.80% |

| Propeller efficiency | 3.02% |

| Aerodynamic efficiency (Cfe) | 2.53% |

| Lift Coefficient (Cl) | 2.00% |

| Rate of climb | 0.25% |

Sensors specifications

The table below lists some of the technical specifications of the different sensors used on the current version of the electronic board.

| Sensor | Mn Value | Mx Value | Accuracy | Resolution | |

|---|---|---|---|---|---|

| TNT-050-02 | |||||

| - Thrust | N | -50 | 50 | 0.10% | 0.01 |

| - Torque | Nm | -2 | 2 | 0.50% | 0.001 |

| TNT-100-05 | |||||

| - Thrust | N | -100 | 100 | 0.10% | 0.01 |

| - Torque | Nm | -5 | 5 | 0.50% | 0.001 |

| TNT-250-15 | |||||

| - Thrust | N | -250 | 250 | 0.10% | 0.01 |

| - Torque | Nm | -15 | 15 | 0.50% | 0.001 |

| TNT-500-30 | |||||

| - Thrust | N | -500 | 500 | 0.10% | 0.01 |

| - Torque | Nm | -30 | 30 | 0.50% | 0.001 |

| TNT-750-50 | |||||

| - Thrust | N | -750 | 750 | 0.10% | 0.01 |

| - Torque | Nm | -50 | 50 | 0.50% | 0.001 |

| Temperature | °C | -20 | 45 | 1° | 0.01 |

| Pressure | Pa | 30 000 | 110 000 | 0.12% | 0.01 |

| Differential pressure | Pa | 0 | 2000 | 1% | 0.01 |

| Voltage | V | 0 | 36 | 0.15% | 0.01 |

| Current | A | 0 | 55 | 0.15% | 0.01 |

| Density | 3.33% | 0.01 | |||

| Load factor | g | 0 | 4 | 1% | 0.01 |

| GPS position | 2m | 0.1 | |||

| GPS heading | ° | 0.3° | 0.01 | ||

| GPS vertical speed | m/s | 0 | 500 | 0.05m/s | 0.01 |

| Air speed | m/s | 2.92% | 0.01 | ||

| Engine RPM | rpm | 1% | 0.01 |

| Sensor | Mn Value | Mx Value | Accuracy | Resolution | |

|---|---|---|---|---|---|

| TNT-050-02 | |||||

| - Thrust | N | -50 | 50 | 0.10% | 0.01 |

| - Torque | Nm | -2 | 2 | 0.50% | 0.001 |

| TNT-100-05 | |||||

| - Thrust | N | -100 | 100 | 0.10% | 0.01 |

| - Torque | Nm | -5 | 5 | 0.50% | 0.001 |

| TNT-250-15 | |||||

| - Thrust | N | -250 | 250 | 0.10% | 0.01 |

| - Torque | Nm | -15 | 15 | 0.50% | 0.001 |

| TNT-500-30 | |||||

| - Thrust | N | -500 | 500 | 0.10% | 0.01 |

| - Torque | Nm | -30 | 30 | 0.50% | 0.001 |

| TNT-750-50 | |||||

| - Thrust | N | -750 | 750 | 0.10% | 0.01 |

| - Torque | Nm | -50 | 50 | 0.50% | 0.001 |

| Temperature | °C | -20 | 45 | 1° | 0.01 |

| Pressure | Pa | 30 000 | 110 000 | 0.12% | 0.01 |

| Differential pressure | Pa | 0 | 2000 | 1% | 0.01 |

| Voltage | V | 0 | 36 | 0.15% | 0.01 |

| Current | A | 0 | 55 | 0.15% | 0.01 |

| Density | 3.33% | 0.01 | |||

| Load factor | g | 0 | 4 | 1% | 0.01 |

| GPS position | 2m | 0.1 | |||

| GPS heading | ° | 0.3° | 0.01 | ||

| GPS vertical speed | m/s | 0 | 500 | 0.05m/s | 0.01 |

| Air speed | m/s | 2.92% | 0.01 | ||

| Engine RPM | rpm | 1% | 0.01 |

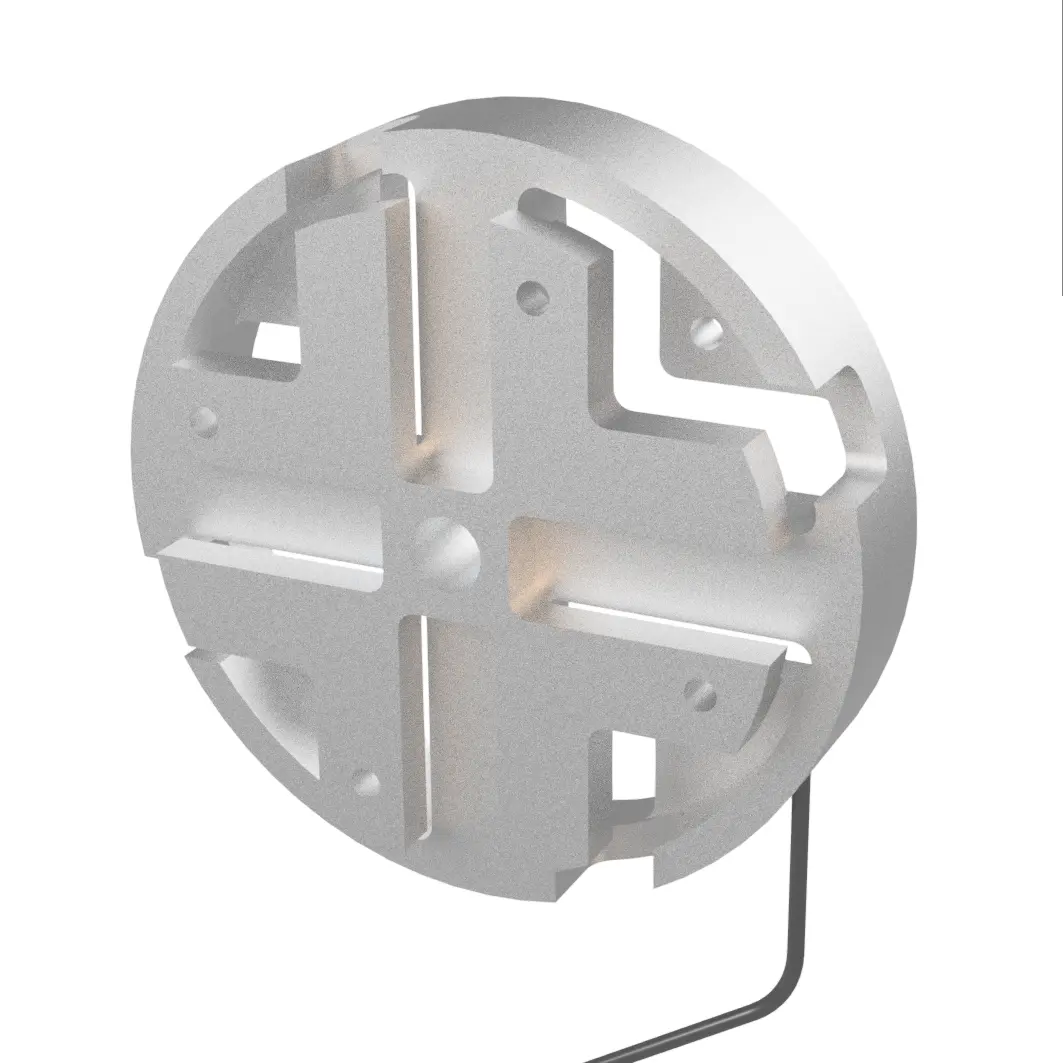

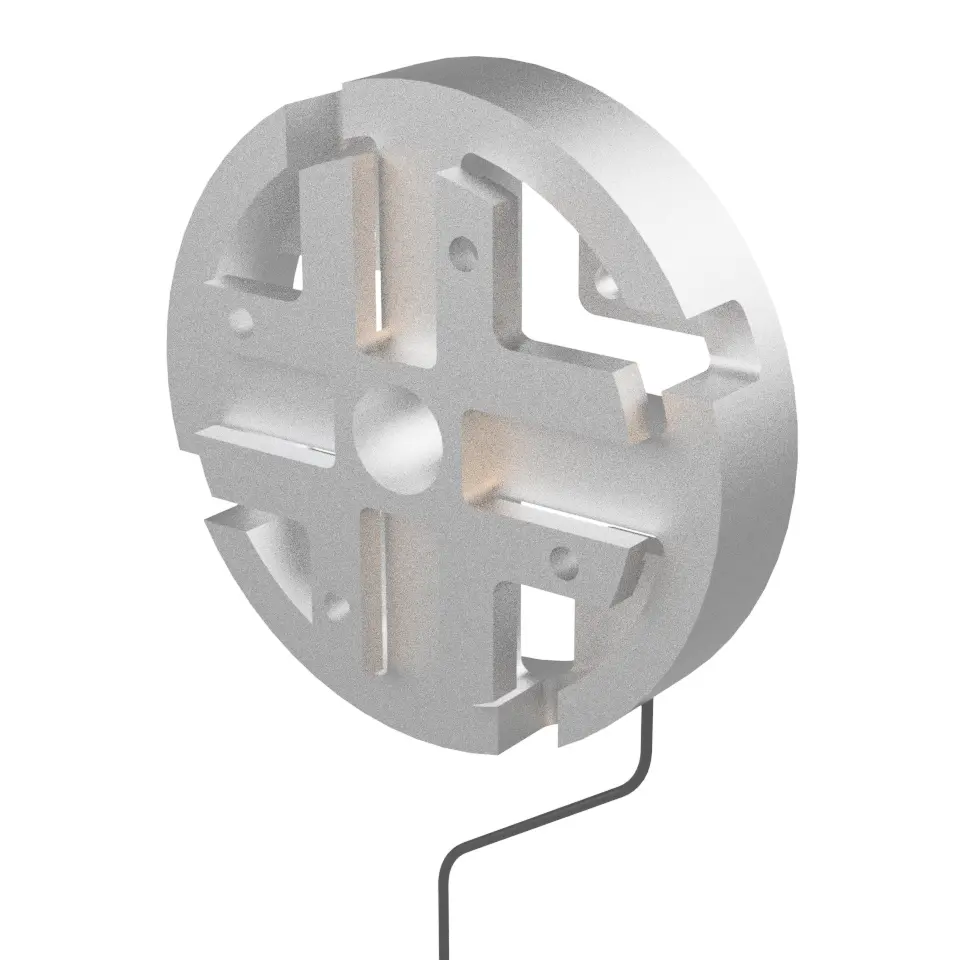

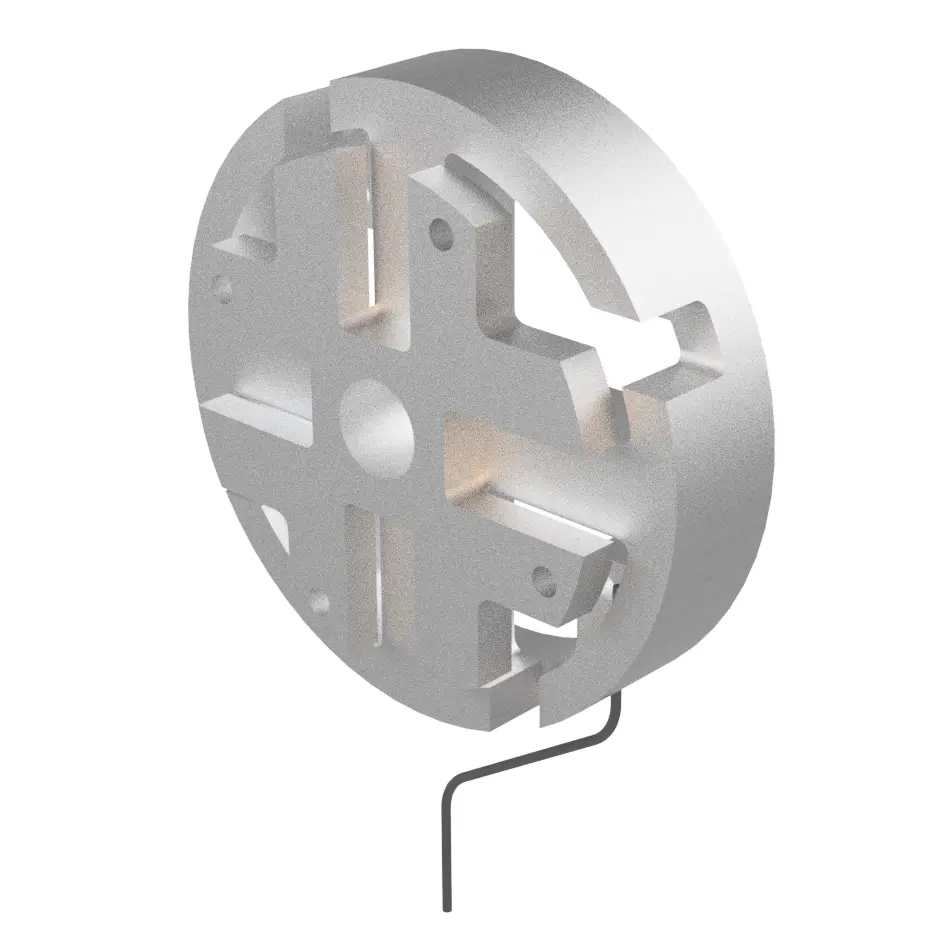

AMS - Technical specifications

| Thrust / Torque sensor | Dimensions | 050-02 | Diameter | 74 mm |

| Lenght | 20 mm | |||

| 100-05 | Diameter | 81 mm | ||

| Lenght | 23 mm | |||

| 250-15 | Diameter | 103 mm | ||

| Lenght | 27 mm | |||

| 500-30 | Diameter | 110 mm | ||

| Lenght | 32 mm | |||

| 750-50 | Diameter | 122 mm | ||

| Lenght | 36 mm | |||

| Weight | 050-02 | 79 g | ||

| 100-05 | 106 g | |||

| 250-15 | 232 g | |||

| 500-30 | 309 g | |||

| 750-50 | 453 g | |||

| Protection | IP 54 | |||

| Electronics enclosure | Dimensions | 93 × 73 × 26 mm | ||

| Weight | 95 g | |||

| Sampling rate | 0,1 – 100 Hz | |||

| Thrust / Torque sensor | Dimensions | 050-02 | Diameter | 74 mm |

| Lenght | 20 mm | |||

| 100-05 | Diameter | 81 mm | ||

| Lenght | 23 mm | |||

| 250-15 | Diameter | 103 mm | ||

| Lenght | 27 mm | |||

| 500-30 | Diameter | 110 mm | ||

| Lenght | 32 mm | |||

| 750-50 | Diameter | 122 mm | ||

| Lenght | 36 mm | |||

| Weight | 050-02 | 79 g | ||

| 100-05 | 106 g | |||

| 250-15 | 232 g | |||

| 500-30 | 309 g | |||

| 750-50 | 453 g | |||

| Protection | IP 54 | |||

| Electronics enclosure | Dimensions | 93 × 73 × 26 mm | ||

| Weight | 95 g | |||

| Sampling rate | 0,1 – 100 Hz | |||